Flexiheat UK

Flexiheat UKWorkshop Heater Wood Burner and Solid Fuel

Workshop heater wood burner or solid fuel warm air workshop heaters – For industrial and commercial warm air heating applications such as joinery workshops, wood processing and wood working facilities, these heaters or burners are a much easier way of converting waste wood, off cuts or logs into usable heat, than using solid fuel boilers with all its associated pipework and unit heaters or radiators, as well as having the benefit that the warm air heat can be delivered quickly and easily making it a quicker heating system compared to a wet heating system.

These workshop warm air heaters are in reality a solid fuel heater as will also burn fuels such as logs, briquettes or briquette (a compressed block of combustible biomass material such as charcoal, sawdust, wood chips, peat, or paper used for fuel and kindling to start a fire) , wood chips, wood scraps, cardboard, paper, vines, nutshells, kernels, which it’s good to know should you run out of your primary fuel which is normally wood, either in a waste wood or log form.

These wood burning workshop heaters or wood burning stoves (as they are sometimes referred to) are designed for the fast and efficient heating of all types of commercial and industrial wood working sectors, as well as agricultural and livestock premises.

These workshop wood waste heaters incorporate a powerful fan that blows the warm air into the room where the equipment has been installed in a free blowing mode, they can also be ducted to move the warm air into other rooms and locations as required.

Workshop wood burning heaters

The benefits of burning waste wood , whether it be from pallets (all nails must be removed !), scrap wood, sawdust or logs is very clear – Cost Savings ! – These workshop wood burning heaters often pay for themselves in a very short period , as the fuel cost is normally zero or negligible , the only cost is for the electricity that powers the fan which is blowing the warm air out of the heater .

They also help the environment , as wood is classed as a CO2 neutral fuel (as wood grows it absorbs CO2 , and when burnt it gives that off – thus neutral) resulting in CO2 neutral heating – so you can be happy in knowing that your doing your bit for the environment and global warming.

Another feature of these workshop wood burning heaters is that they help eliminate your bulky and often expensive to get rid of waste wood product, saving thousands of pounds a year on skip and landfill charges, and turn it into heat for you to benefit from, as well as saving energy usage.

These wood / log burners are not designed to burn MDF (chipboard), particle board or plywood, these contain glue, which release toxic fumes and carcinogens when burned.

Workshop wood waste heaters

Instead of wasting money by paying ever increasing fuel bills, you can save your business thousands of pounds each year by burning your wood waste cleanly and efficiently instead. Most of our clients recoup their initial investment in less than 12 months and thereafter continue to enjoy the money saving benefits for many years to come.

The key benefits of these workshop heater wood burner range are –

- They have a fast payback on investment/capital employed

- They provide continual money saving – via no heating fuel costs

- You can future proof your business from ever rising energy costs

- You can reduce your businesses carbon footprint

- And also increase your company’s ‘green’ climate credentials and benefit from being an environmentally responsible business

- They have a small footprint

- Ease of installation

- Virtually maintenance free

Workshop Heater Wood Burner Specifications

- Simple design for trouble free operation

- The fan can be located on the left or right side of this wood burning workshop heater range

Centrifugal fan or blower for our wood burning warm air heater – can be fitted on the left or right hand side on the units, to suit site conditions

- Refractory bricks (insulation) in the combustion chamber to increase heat accumulation

- Robust steel casing coated with high temperature powder coating resistant to 600º Centigrade

- Large fuel door and opening -making refuelling a breeze

- Manual ignition system

- Large removable ash box – making cleaning the unit easy

- CE certified and approved

- Please note that ventilation of the area where the workshop wood burning heater is situated is required to prevent a deficiency in oxygen supply

- Please note that these do not qualify for Renewable Heat Incentive (RHI) payments because they heat air directly, rather than heating water like a biomass boiler heating system

- Loading hatch, to ensure your safety when refuelling these workshop heater wood burners

- These “EPC” wood burning heaters may work in either ventilation or air circulation only mode or heating mode

The unit has a centrifugal fan, which allows you to connect a duct work system to the heater, up to 20 metres – but this depends on the duct diameter, and the pressure drops of the fittings used on the duct system. Please consult a duct work specialist for this aspect of ductwork sizing.

Our heater connected to a duct work system to move the warm air to another area.

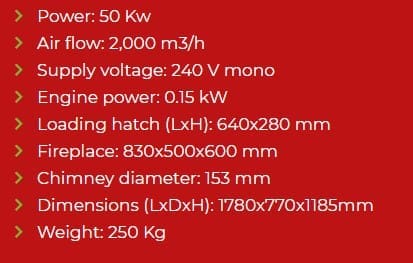

Waste Wood Burning Workshop Heater Technical Data

For the 50kW model – Generally good for a building volume up to 1,200 m3

50kW input – thus 50kW x 85% combustion efficiency = 42.5 kW output

and for the 100kW model – Generally good for a building volume up to 2,500 m3

100kW input – thus 100kW x 85% combustion efficiency = 85 kW output

The construction of these “EPC” wood burning workshop heaters is compliant with the EN 13240:2008 standard. According to this specification, these workshop wood waste heaters are in the category of devices loaded manually “1a” – free standing with closed furnace doors, with periodic combustion. The “EPC” workshop heater wood burners are designed for firewood combustion of deciduous trees such as birch, alder, oak, beech, ash, maple, hornbeam, etc with a moisture content of no more than 20% .

In the case of the “EPC50” the usable thermal power enables room heating of areas with a total maximum volume of 1,200 cubed metres and 2,500 cubed meters while using “EPC 100” model workshop heater wood burner.

These heaters meet the requirements of European directives 2006/95 / EC, 2004/108 / EC, and 89/106 / EC and also comply with the following standards: EN 60335-1 , EN 60335-2-102, and EN 13240.

CAUTION! It is forbidden to use the workshop log burner where the air is polluted with dust or flammable substances (i.e. gasoline’s, gas, paint thinners, petrol etc).

Download the Flexiheat brochure for EPC workshop wood burning heaters

Flexiheat Manual for FH50ECP and FH100ECP Wood Burning Warm Air Heaters

While installing of the “EPC” range of waste wood workshop wood burning heaters all the regulation and corresponding European and local standards have to be followed. Particularly:

EN 13240:2008 Room heaters fired by solid fuel – requirements and test methods

EN 1443:2005 Chimneys – General Requirements

EN 1457-2:2012 Chimneys. Clay/ceramic flue liners. Flue liners operating under wet conditions. Requirements and test methods.

These wood burning warm air heaters are to be located on a horizontal, stable, non-combustible and flat surface with appropriate load bearing capacity. Locating and using these wood burning workshop heaters near flammable materials is strictly forbidden.

Combustion Air Requirements

The area or workshop where the war air heater is to be located must have an adequate combustion air supply ventilation, which will provide sufficient volume for the fuel combustion process. To ensure the correct running of these workshop wood waste heaters it is necessary to supply the heaters with combustion air with at least 10 m3/hour of air volume for every 1kW of heating power and at least 20 m3/hour of air volume per person located in the area being heated.

Workshop wood burning heaters

Both the FHEPC wood burning heaters require and are powered electrically by a 240 volt, 1 Phase supply.

You will notice that theses FHEPC workshop heater wood burner heaters have a large fuel access door

This access or fuel feeding door gives access to the combustion chamber and flue exit – making cleaning the unit easy. This access door is also used to feed the heater with fuel when using solid fuels.

In times of rising fuel costs, the payback period for a workshop log burner heater is very short. Utilising your waste wood / logs etc, you can get an effective warm air heater with no fuel costs, and no fees to pay for the collection and disposal of your waste wood. The Flexiheat EPC range is in our opinion is the best workshop heater wood burner heater for your workshop or garage available in the UK and Ireland.

Workshop Heater Wood Burner for Sale UK & Ireland

Should you require anymore assistance or information on our comprehensive range of Workshop wood waste heaters / Workshop Heater Wood Burner/ Wood Burning Workshop Heater, please don’t hesitate to contact our sales team on 01202 822221 or click here for our email contact form

Flexiheat UK

Flexiheat UK Flexiheat UK

Flexiheat UK