Flexiheat UK

Flexiheat UKWall Mounted Electric Commercial Boilers – 18kW to 96kW Output

Wall mounted electric commercial boilers -18kW to 96kW from Flexiheat UK – can be floor mounted with our floor mounting frame kit

Our wall hung commercial range of electric boilers are 100% energy efficient and requires a three-phase electrical supply at these sizes, with a wide range of outputs from 28kW to 96 kW. These commercial electric boilers can be used as the primary heating source for the hydronic heating system, or as reserve or top up heating for heating pump systems etc. These central heating electric boilers are not equipped with a pump or expansion vessel; these are by others.

They can be used in a cascade boiler configuration for large output requirements in commercial buildings, as you can cascade up to 10 of these commercial electric wall hung boilers (thus up to 960kW of output for this electric boiler range)

Our electric boiler is a 100 percent energy efficient, intelligent modulating boiler that combines established commercial technology in a one-of-a-kind design to provide the client with one of the most advanced and efficient electric boilers on the market.

These 3 phase electric boilers can heat an indirect hot water calorifier / cylinder and a wet central electric heating system, whether they be radiators, underfloor heating, or a combination of the two, with the same simplicity and control as an oil or gas boiler (natural gas or LPG systems)

These highly efficient electric boilers have numerous advantages because they do not vent fumes from a combustion process and thus a flue or chimney system is not required, installation is inexpensive and easy to get done. The units are extremely quiet in operation, come with a three-year warranty, require very little maintenance, and more importantly require no annual safety check unlike gas and oil boilers do.

Wall mounted commercial electric heating boilers

These wall hung or wall mounted electric boilers are commercial electric boilers for hydronic heating. On the control panel, the flow temperature can be regulated to a wide temperature range (20-90 ° C) for radiator heating or 15-45 ° C (for underfloor heating) in 1 ° C increments.

Technical features of the wall mounted electric boiler:

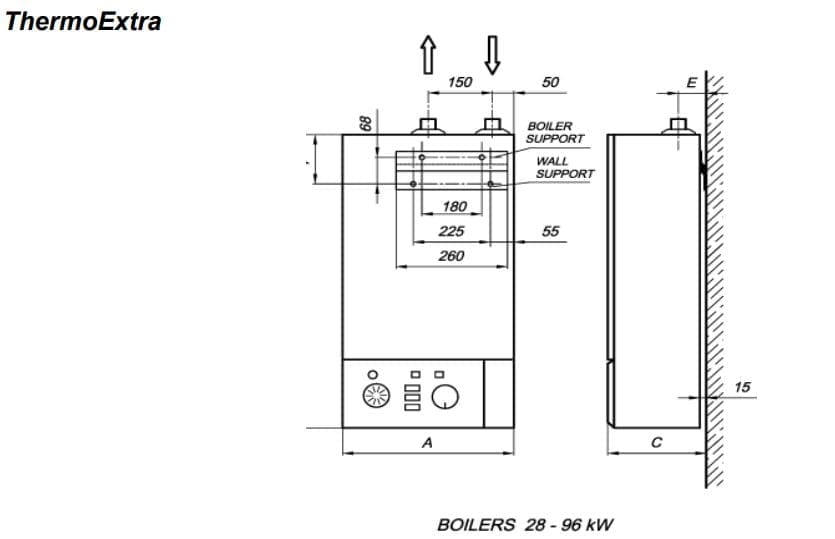

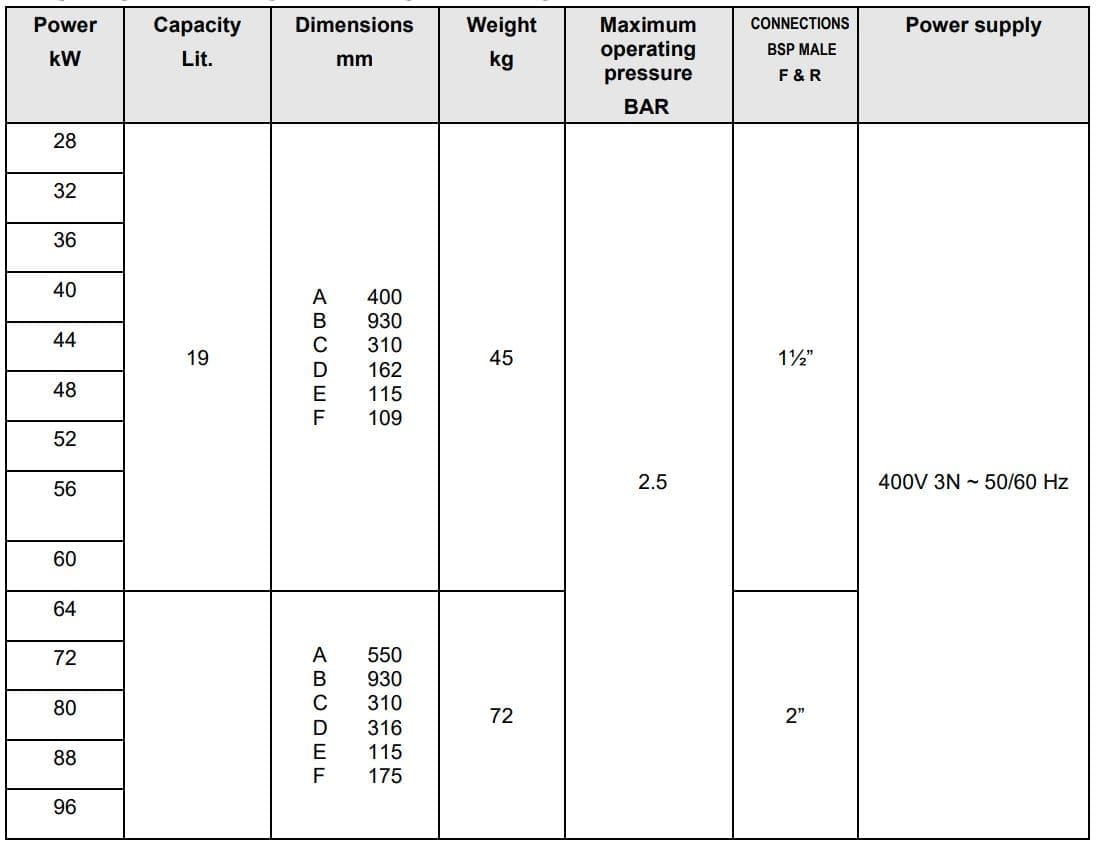

Top mounted flow and return heating system connections – 2 ” (50mm) for the 64kW to 96 kW and 1 1/2″ (40mm) for the 28kW to 60kW output boilers, 1″ for the 18kW to 24kW electric boilers.

Operating system pressure – minimum 0.8 Bar and the maximum is 3 Bar for the models up to the 24kW output,and 6 Bar for the 28 to 96kW models

Please ensue you have a safety valve fitted to the water heating system to prevent over pressure of the boilers.

Bottom design fill / drain connection and valve

Electric boiler water temperature sensor (with electronic, digital display)

Boiler overheating safety thermostat, connected to a circuit breaker / FI relay (manual boiler restart required)

Boiler body air presence sensor (automatic boiler restart after the air has been removed from the electric boiler)

Low voltage safety switch (automatic boiler restart)

Boiler body with 4 mm thick steel and high density thermal insulation – 20mm for the 18-60kW models and 50 mm 64- 96kW output models

Incoloy (a category material of super austenitic stainless steels) electric immersions heaters / heating elements

Heating elements are controlled in seven power modualtion steps, ensuring close control of water heating for this electric wall mounted commercial boiler range.

Boiler control based on the PID principle, which ensures precise power control

Outdoor temperature-corrected operating temperature with the possibility to select and shift to pre-defined heating curves (with optional outdoor temperature sensor)

Boiler flow heating water temperature control

Indirect DHW tank temperature control, DHW tank with frost protection (switches on below 7 ° C) with optional immersion tank sensor.

Manual limitation of boiler maximum power in 3 power steps

Automatic boiler and heating system frost protection when switched off (switches on below 8 ° C)

Construction of the total output of the boiler as a power step with time offsets of 15 seconds- can be adjusted to 220 seconds depending on the system requirements

Boiler body pressure test during production, after welding the boiler body and complete assembly of the boiler are tested

Boiler electrical insulation test (500 V) at the end of the boiler manufacturing process

10-year warranty on boiler body welding quality or water leakage

36-month warranty on the boiler’s built-in electrical components

Digital and modular heating power control between 0-100%, according to which the number and power of the heating groups and/or heating inserts are switched on or off automatically according to the current heat demand. Thanks to the intelligent PID control, the electric boiler only operates at maximum output for higher heating or domestic hot water capacity requirements.

Product details

| Thermo Extra Electric Boiler | 18 – 24 | 28 – 60 | 64 – 96 |

| Energy class | D | D | D |

| Heating energy output | 18, 20, 22, 24 kW | 28, 32, 36, 40, 44,48, 52, 56, 60 kW | 64, 72, 80, 88, 96 kW |

| Dimensions and weight | |||

| Width | 400 mm | 400 mm | 550 mm |

| Height | 750 mm | 930 mm | 930 mm |

| Depth | 230 mm | 310 mm | 310 mm |

| Weight | 32 kg | 45 kg | 72 kg |

| Power supply – 415Volt /50Hz | |||

| Three phase electric required | YES | YES | YES |

The full range brochure is here –

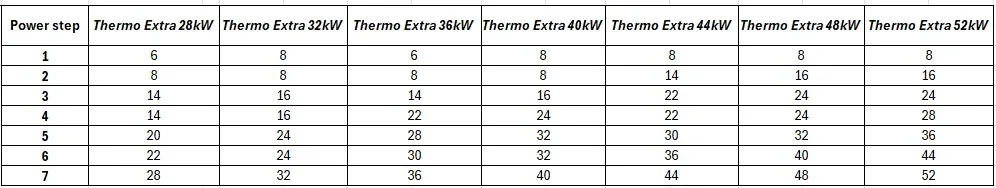

Thermo Extra Electric boiler modualtion output steps or levels

All this range of wall hung electric commercial boilers has seven power outputs or steps, meaning the boiler will modulate 7:1 to suit the demand of the heating system.

You can also set the boiler to a maximum output level, and the boiler will ramp up and down to your set desired output level.

Our 28kW to 52kW electric boiler range power output modulation steps – each boiler has 7 power output levels or steps.

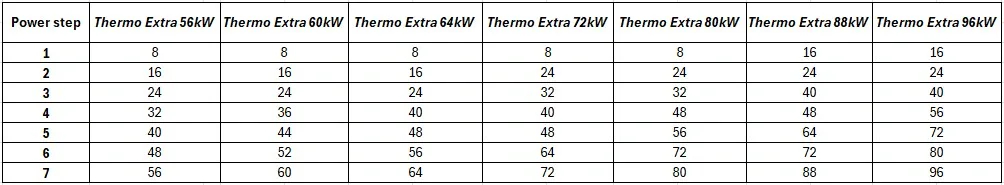

Then the larger electric boilers, 56kW to 96kW

Our 56kW to 96kW electric boiler range offers power output modulation steps; each boiler has 7 power output levels or steps.

Dimensions

Technical data for wall hung electric boilers from Flexiheat UK

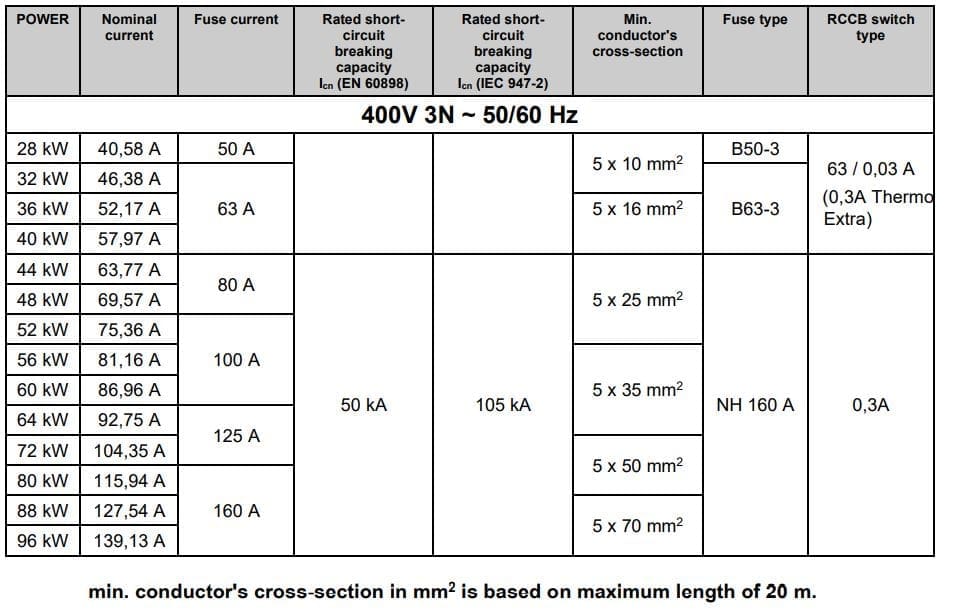

Power supply characteristics and requirements

Power supply characteristics of our wall hung electric boilers, 28kW to 96kW, from Flexiheat UK

For all wall mounted electric commercial boilers from February 2024, with our new “X” control panel – this is the technical and installation manual to download

For boilers before February 2024, which had the older control panel options, here is the correct technical and

installation manual for these

Download the Flexiheat Thermo Extra 28-96kW Wall Hung Electric Boilers Technical Manual

Floor mounting these electric boilers

You can install these wall hung electric commercial boilers in a “floor mounted configuration” via the use of our purpose made floor mounting kit for easy installation.

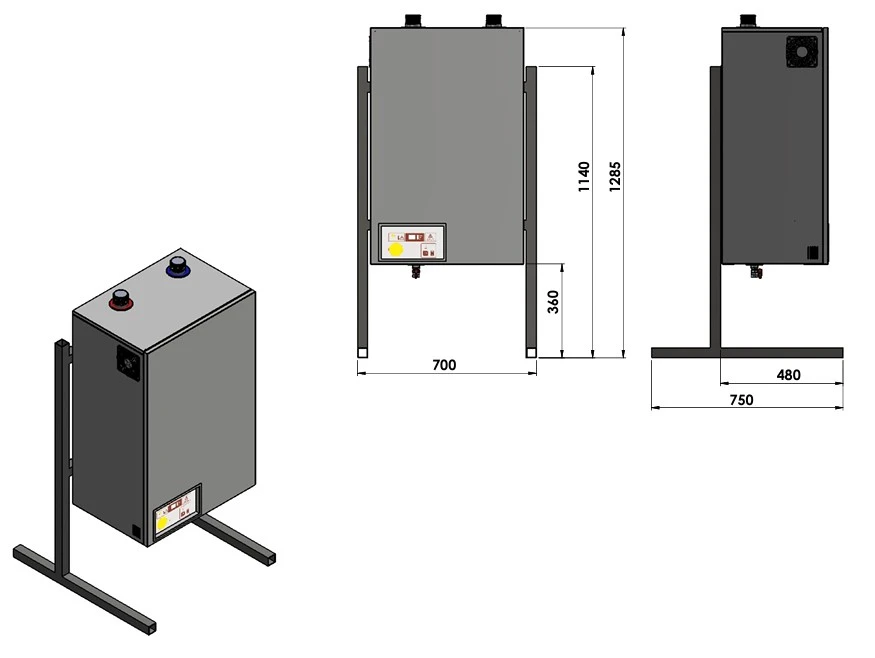

Floor mounting boiler frame kit for our 28kW to 96kW Wall hung electric commercial boilers, which converts the boilers into free standing floor standing electric boilers.

Floor standing frame kit dimensions

Purpose made floor mounting kit for these electric commercial boilers

Or you can make your own “unistrut frame ” like below (N.B. picture just for illustration purposes – these are not electric boilers and are not to be fitted outside – for the purpose of showing a floor standing strut frame installation). Please note that the minimum distance from the floor to the bottom of the boiler needs to be 360mm for maintenance requirements.

Using a strut frame to change these commercial wall mounted electric boilers into a floor mounted installation – (Strut by others)

Control Features

Our new “X” panel is a “comprehensive control panel” – with all the options of weather compensation, and control of a DHW indirect cylinder all in one panel.

X control panel for our wall hung commercial electric boilers

The “X” control panel has the following features

- Multilingual control panel with lcd display

- Date and time

- Weather compensator – when an outside temperature sensor is used

- Control of a commercial indirect hot water cylinder for domestic hot water production – when an immersion temperature sensor is used

- End user menu

- Installer’s menu protected with a password

- Rapid heating function when using the weather compensator feature

- Cascade control – Up to 10 electric boilers can be cascaded with a simple 2-core x 0.75 mm2 cable

- Circulation pump lock protection

- Automatic air venting of the unit

- Over run for heating and DHW pump

- PID regulator with up to 7 power steps/output levels, depending on the output of our high efficiency boiler.

- Delay between power steps/output levels

- Limitation of maximum boiler power

- Protection from air in the boiler, low voltage, freezing, low or high pressure in the electric boiler

- External limitation of the maximum power of the commercial electric wall mounted boiler

- External signal for displaying alarm and the active power of these wall mounted commercial electric boilers

The BMS compatible control panel specifics/functions are:

Inputs:

Two temperature sensors

Safety thermostats switch off.

0-10 Volt analogue signal for set point temp or % of power output

On/off signal

Outputs:

Error signal

0- 10V temperature signal or % of power (power steps)

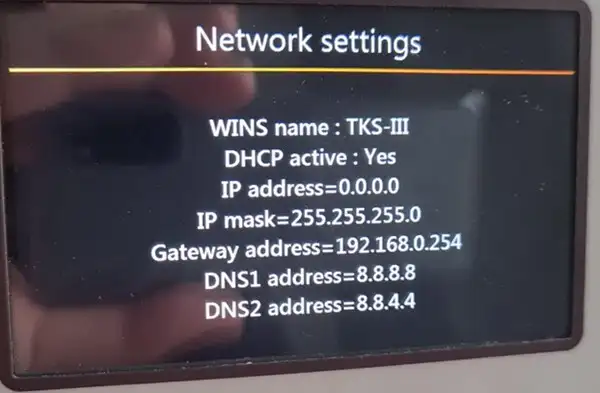

Modbus TCP: RJ45 connection, Dynamic Host Configuration Protocol (DHCP) which is a client/server protocol that automatically provides an Internet Protocol (IP) host with its IP address and other related configuration information such as the subnet mask and default gateway.

Modbus TCP: RJ45 connection, Dynamic Host Configuration Protocol (DHCP) which is a client/server protocol that automatically provides an Internet Protocol (IP) host with its IP address and other related configuration information such as the subnet mask and default gateway.

Electric commercial boilers – Wall Mounted

Should you require anymore assistance, prices, or information on our floor or wall mounted electric commercial boilers for sale in the UK and Ireland, please give us a call on 01202 822222, and our dedicated sales team will be happy to offer advice and assistance, or contact us by mail by clicking here

Flexiheat UK

Flexiheat UK Flexiheat UK

Flexiheat UK